WHEEL CHOCKS - buy wheel chocks for a wildland water tender

Ok simple little task...

Acquire NFPA1906 compliant wheel chocks for a wildland fire tactical water tender.

What brands are wild land fire compliant? How do you know the specs?.

What is SAE J348? What is NFPA 1906?.

Solid bottom? 10% grade, 15% grade or 30% grade which is it? .

What is readily accessible? Can I find a definition?.

So I start with NFPA 1906 Standard for wildland apparatus 2006 edition. Advertised as

Ensure that wildland fire apparatus are up to the task!

NFPA 1906 defines the requirements for a new automotive wildland fire apparatus, including apparatus equipped with a slip-on fire fighting module, designed primarily to support wildland fire suppression operations.

Finding the actual text online in the NFPA HANDBOOK dealing with wildland appuratus is difficult by design apparently. The NFPA sells the text in softback and PDF online but I do not need the whole thing just one section, just one sentence! They allow you to review it here. And eureka I found the actual text in the NFPA HANDBOOK !

So this is the actual text in the 2006 NFPA Handbook 1906 12.2.1 minor equipment.

(1)*Two solid bottom wheel chocks, mounted in readily accessible locations, each designed to hold the apparatus when loaded to its GVWR, on a 10% percent grade with the transmission in neutral and the parking brake released.

I was unable to find out what the Astrix denotes... that is worrisome.

Cuts and snips from the internet:

Google search results for key words SAE J348 nfpa 1906 combined: Web Results 1 - 8 of 8 for SAE J348 nfpa 1906. (0.27 seconds)

Only eight results not much out there! And the third one really confuses things! It is a meeting minutes for a Fed R1 equipment committee.

Wheel Chocks: Spec/standards SAE J348 is flawed. Chocks.com has guideline on number of chocks required for various degrees of grade. Must comply with NFPA.

Basic requirements are that chock must be planed, solid (not officially out yet), with handle. Height depends on tire size – should be level with rim.

Rich Grady will follow up

Ok thats a bit confusing must be solid? but it is dated 12-02 so hopefully we can just ignore that anyhow moving on ...

so we will go to CHOCKS.COM and what do we find out?

Nice clean website but the search engine seems broken no returns on keyword nfpa 1906?

"Question: What is SAE J348 and what is its use.

Answer: SAE J348 is a standard set by the Society of Automotive Engineers that predicts the potential of any one wheel chock given a worst case scenario.

What the hell does that mean? that's it? At least give me a citation for that statement...

we will hopefully return to these questions

So we continue surfing chock.com

I like these chocks at chocks.com price is right they look sturdy and professional but are they compliant?

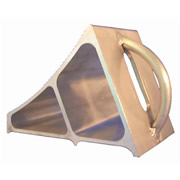

Model HGS molded aluminum

I have learned the first thing I am looking for is a solid bottom which is required in NFPA 1906 for wildland fire fighting.

And this catalog description does not answer this question.

So I call them at chocks.com and get real person Doug on the line who tells me they are compliant and solid bottom chock known as a SBC and supplied a photo

but suggested this chock the model HWC-7H

Model HWC-7H extruded aluminum

Ok these are great looking, well designed, but we need to make sure they are compliant how?

Doug says they are!

They sure look great!

they are eight inches tall which should be good for my truck since the bottom of wheel rim to ground measures exactly eight inches.

to be continued..

Day 2...

Searching for information I find that the The City of Elko Nevada Fire Department specs these HWC7H wheel chocks... Sweet!

Specifications are for an Interface fire apparatus.

Next

Ok so I find this wheel chock discussion dated September 2004 on wildland fire.com

9/16 Wheel chocks:

NFPA Standard 1906 for Wildland Fire Apparatus

2 wheel chocks with solid bottoms

Each wheel chock must hold a fully loaded vehicle on a 15% slope

2 wheel chocks must hold a fully loaded vehicle on a 30% slope

Wheel chocks must have a height as high as the bottom of the rims on the

truck that it will be used with

Wheel chocks must have a solid bottom to prevent sinking in soft soil

Wheel chock must have a face beveled at a 30-50 degree angle

Wheel chock must be 2/3 as wide as the tire

Wheel chock base must be 1.4 times the height or greater

Wheel chock must have a heel behind the top tire contact point of the chock

as long as 1/2 the height of the wheel chock

The source of this information was the NRCG equipment inspectors workshop,

hope that helps.

MT Smokey

I wish Smokey had left some links to citations for this list I have no idea where this list officially came from we will ignore it for now

Day 3

Off to a yearly hired equipment refresher course more information sent to me will post next week...

This is my list as I learn more subject to change:

Requirements for Wildland Fire apparatus wheel chocksNote: Last year I was told by a Fed hired equipment / water tender inspector that they had to be metal so far no joy finding a reference to that requirement?

- Two Chocks must be mounted and readily accessible.

- Chocks must be solid bottom.

- Chocks designed to hold the apparatus when loaded to its GVWR, on a 10% percent grade with the transmission in neutral and the parking brake released.

This will be a list of Wheel chock rules, do's and dont's:

NFPA standards require wheel chocks to be mounted on fire apparatus before being placed into service. Two Chocks must be mounted and readily accessible per NFPA 1901 (Section 7-2), 1902 (Section 7-2), 1903 (Section 6-1) and 1906 (Section ?-?)

- Wheel chocks should be placed in front of and behind the drive axle on the driver’s side of the vehicle or, in the case of a tandem axle, between the axles.

NFPA 1906, Standard for Wildland Fire Apparatus, was published in 1995 to provide a standard for apparatus that are designed and deployed to combat fires in wildland. The document covered apparatus with pumps ranging in size from 20 gpm to 250 gpm (76 L/min to 950 L/min) and water tanks with a capacity of 125 gal (473 L) or more.

Requirements were also provided for the first time for foam proportioning systems using Class A foam as a fire suppressant agent and for Compressed Air Foam Systems (CAFS). The apparatus covered in the standard included built-to-specification apparatus and fire-fighting packages designed to be slipped onto a vehicle chassis.

The 2001 edition updates the 1995 edition. The requirements for low-voltage electrical systems, including the emergency warning systems, have been moved to a separate chapter and brought in line with the requirements in NFPA 1901, Standard for Automotive Fire Apparatus. The pump chapter was reorganized to provide requirements for four types of pumps with the range of pump sizes changed to include pumps from 10 gpm (38 L/min) to 500 gpm (1900 L/min). The allowable minimum size on water tanks was lowered to 50 gal (190 L), and the chapter on line voltage systems was removed. The document was updated where appropriate to make the requirements consistent with those in NFPA 1901.

No comments:

Post a Comment